CASTING TECHNOLOGY

Optimum results are achieved through experience and a feel for the material and the use of our modern technologies under the control of experienced technicians.

Materials

We manufacture grey cast iron and nodular cast iron in various alloys on the highest level. Depending on requirements, also wear-resistant and heat-resistant materials.

Livarna Gorica

Overview

- Cast iron with lamellar graphite DIN EN 1561, EN-GJL 150 to 300

- Cast iron with nodular graphite DIN EN 1563, EN-GJS 400-18 to 600-3

- Special casting, special alloys, e. g. wear resistant cast iron

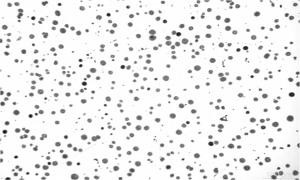

In grey cast iron, the graphite is in the form of thin, irregularly shaped lamellae. The material has a medium tensile strength, but the compressive strength is much better when transmitting compressive stresses. The structure gives cast iron with lamellar graphite very good sliding properties due to its high resistance to friction wear. In addition, grey cast iron is easy to process and dampens mechanical vibrations. The positive properties result from the three-dimensional branching of the lamellae. Furthermore, this graphite form ensures good thermal conductivity. In combination with the self-lubricating effect of the graphite, the material has good emergency running properties and is therefore very suitable for engine components. With its good castability, grey cast iron is excellently suited for complex castings. We manufacture cast components from iron castings with lamellar graphite according to DIN EN 1561 in the alloys EN-GJL 150 to 300 for the respective application.

- high compressive strength

- good gliding properties

- dampens mechanical vibrations

- high thermal conductivity

- good castability

Nodular cast iron has a very high ductility, as the notch effect is minimal due to the spherical formation of the graphite. Cast iron with spheroidal graphite also has an extremely high strength, whereby the material achieves a high tensile strength with a good elongation at break. In most cases, these values are higher for nodular cast iron than for cast steel. Another positive factor is its good machinability, for optimal mechanical processing. This is achieved by desulphurising the melt. Wear, temperature and corrosion resistance of this material can be further increased by alloying. For the right choice of alloy for the optimal application, we take into account the specific requirements of the end product. For this purpose, we produce cast iron with nodular graphite in the alloys EN-GJS 400-18 to 600-3.

- high ductility

- high tensile strength

- good elongation at break

- minimal notching effects

- good machinability

CONTACT US

Livarna Gorica d.o.o.

Cesta IX. Korpusa 116

5250 Solkan / Nova Gorica

Slovenia