CASTING TECHNOLOGY

Optimum results are achieved through experience and a feel for the material and the use of our modern technologies under the control of experienced technicians.

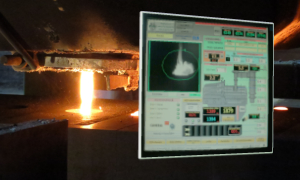

Casting process

Our fully automatic, camera-controlled casting plant makes it possible to produce castings with the best possible properties. Continuous temperature monitoring during the casting process ensures a homogeneous structure even for complex components. We control the supply of the casting melt by camera guidance, whereby the gating and supply technology, which is optimally matched to the respective component, is of major importance. The components are cooled gently on our 63-metre-long cooling line.

Livarna Gorica

Overview

- fully automatic and camera controlled casting process

- Modell Progelta 1,5 t / 2,0 t

CONTACT US

Livarna Gorica d.o.o.

Cesta IX. Korpusa 116

5250 Solkan / Nova Gorica

Slovenia